|

|

|

|

|||||||||||

|

|

||||||||||||

|

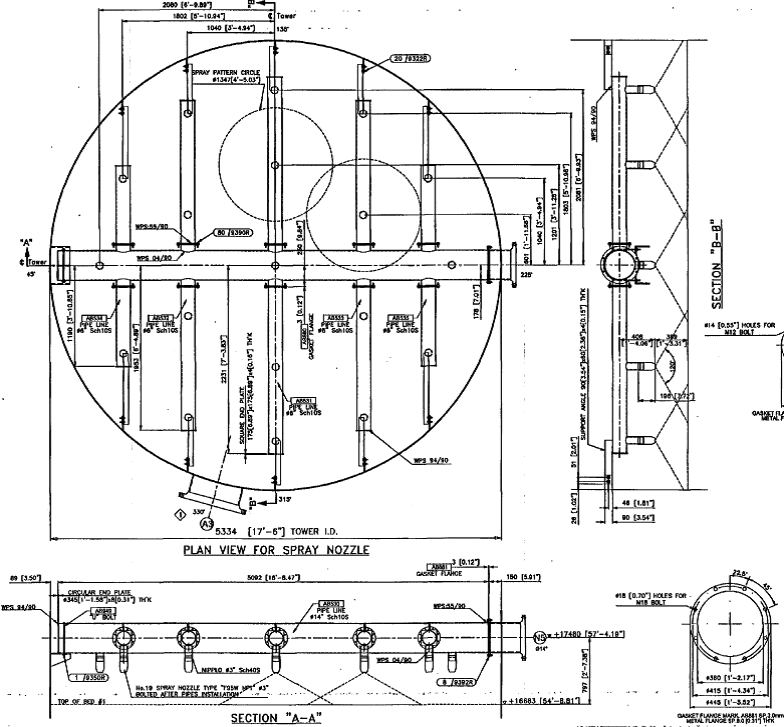

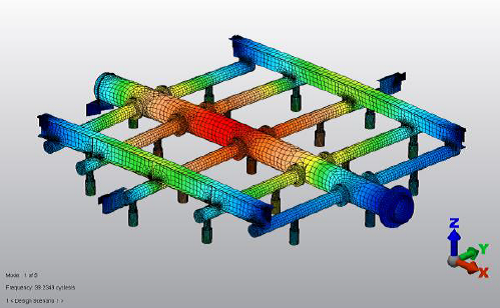

Equipment:Gas Condensate Distillation Unit Pre-flash Column Internal Distributor Pipe System |

|

Problem: Repetitive Failures were observed on the primary and secondary distribution header of the pump around internal piping of Pre-flash Column. These failures consisted of shearing away of the distribution nozzles, primarily from the parent metal of the 4in & 8ni pipes. Additionally, one 3in€¯ spray nozzles threaded connection was damaged. The material of this distribution header / piping is primarily SS 304L. The failure mechanism seems to be a combination of flow-induced mechanical vibration causing fatigue, coupled with inherently defective base metal and previous welds. Nevertheless, the internal piping was not currently designed to adequately withstand the internal fluid-dynamics loads. |

|||||||

|

Analysis: The defective nozzles failed due to thermal fatigue and accelerated by vibration. The tube failed due to thermal fatigue in the form of trans-granular and non-branching cracks, which initiated at high stress concentration area within the attachment welds and extended outward to the adjacent base metal The nozzles must have gone through many thermal cycles (temperature fluctuation) until they cracked. The spraying mechanism of the nozzle may have introduced vibration which accelerated the crack propagation. As a part of mechanical analysis, the Finite Element Analysis (FEA) on existing Spray Nozzle Distributor at Medium Naphtha Pump around Return to compute its natural frequency was done and found that these natural frequencies fell in a critical range considering the column diameter and operating regime. These natural frequencies are exactly within the most critical frequency range and the existing spray distributor has been damaged by vibration fatigue. As per industry know vibration tests, the strongest vibrations (causing the worse damages) occurred between 20 and 30 Hz. |

|||||||

|

|||||||

|

|||||||

|

|