|

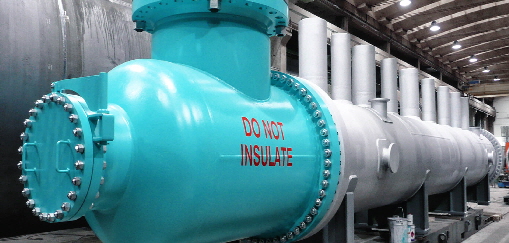

At SAS we perform stress analysis typically required for design and failure analysis of static pressure equipment installed in Refineries, Onshore and Offshore oil producing facilities.

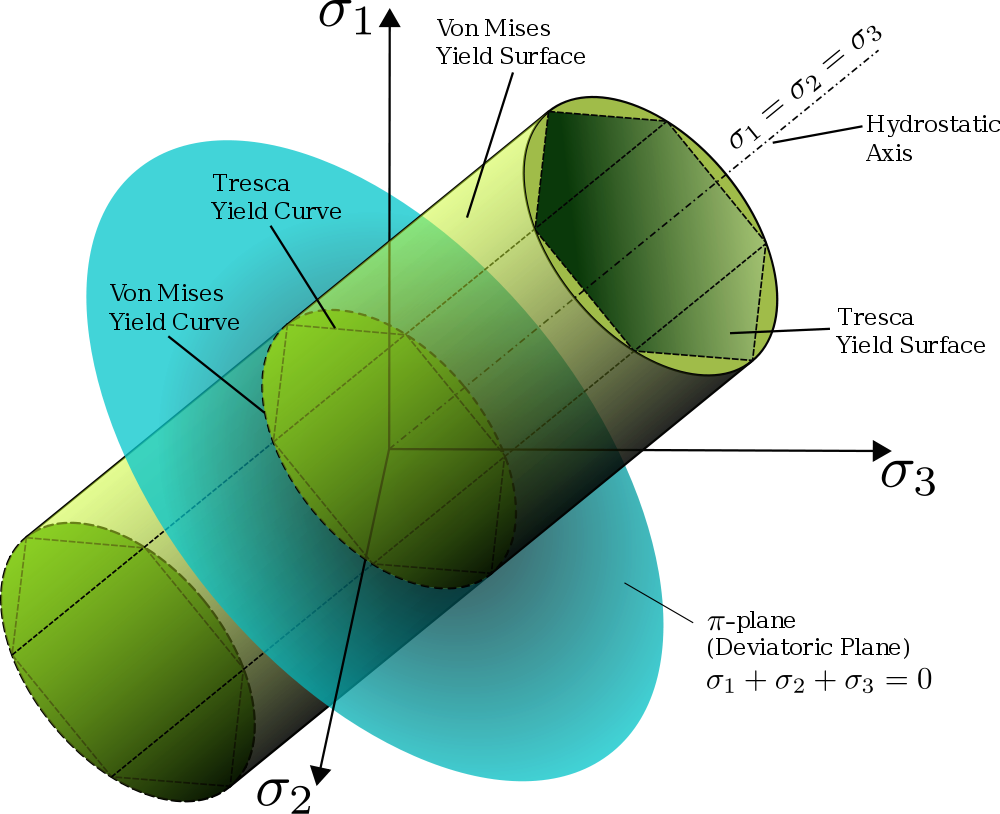

Stress analysis involves establishing magnitudes of the stress components at each point of the body that is subjected to mechanical / fluid / thermal loads that may be either static or dynamic in nature.

At SAS we utilize the numerical technique of Finite Element Analysis (FEA) to enable the use of computers to solve the partial differential equations (PDEs) which are essentially utilized to comprehensively understand and quantify any physical phenomena such as structural or fluid behavior, thermal transport, wave propagation, etc.

The PDEs governing the physical behavior are solved in order to compute relevant quantities of a structure like stresses (σ), strains (ϵ) in order to estimate a certain behavior of the investigated component under a given load.

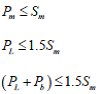

Finally the results from a stress analysis are provided to evaluate components for plastic collapse, local failure, buckling, and cyclic loading based on ASME Sec-VIII Div-2 and/or API-579 rules and acceptance criteria.

|