|

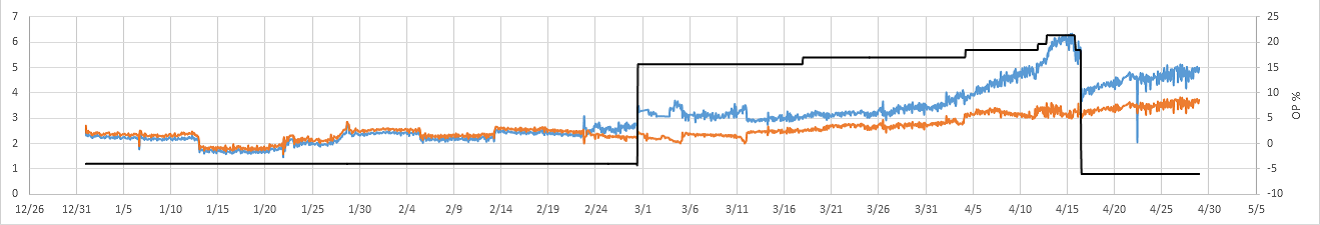

Problem:As recommended by process licensor, the maximum allowable pressure drop for the vessel was dependent on the design of bottom collector set at 10 psid. Due to a planned change in type of Absorber materials, the dP (pressure drop) across the vessel exceeded well before the EOR schedule of 6 years before absorbent change-out. This caused multiple outages in the gas-condensate distillation operations resulting in loss of production $$$.

|