|

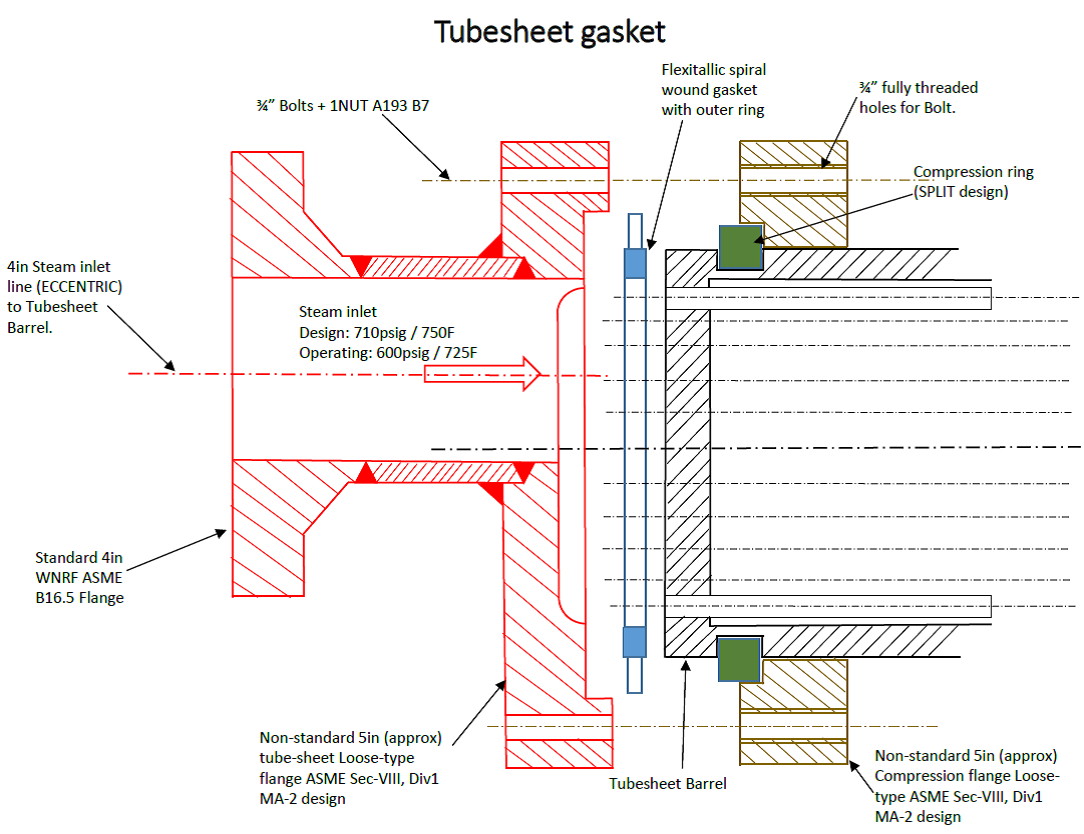

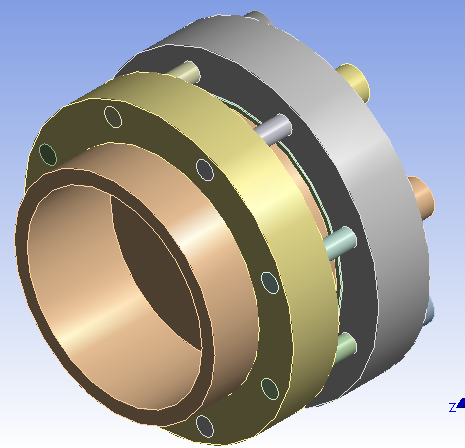

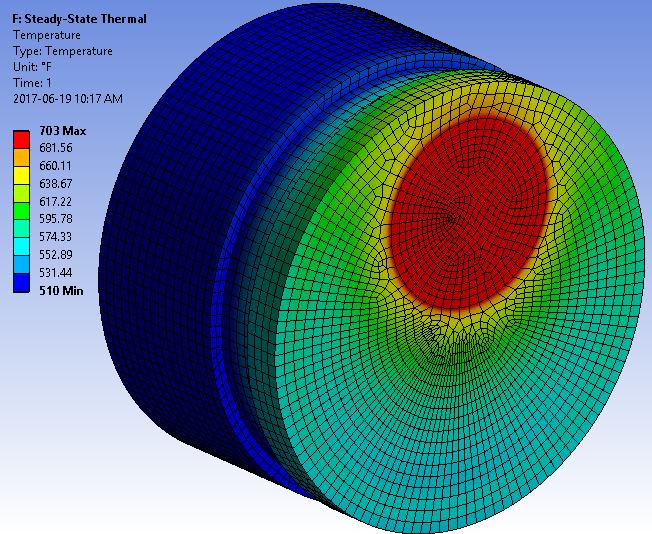

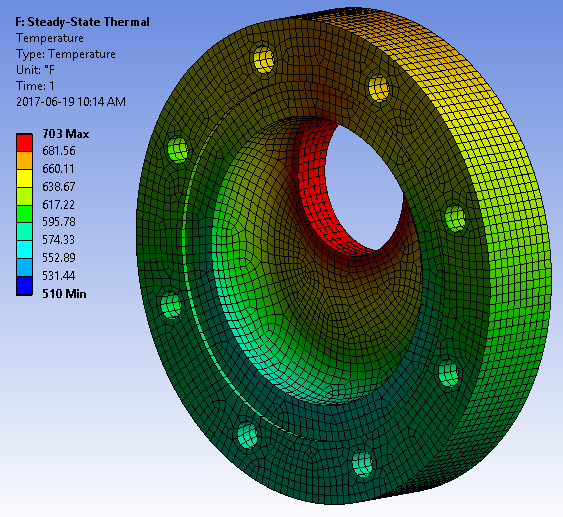

Analysis: The ASME B31.3 and ASME Sec-VII MA-2 calculations confirmed that the piping loads on the tubesheet nozzles and the flange design stresses were well within acceptable limits. Additionally, the WRC-510 calculations confirmed that the resulting bolt load during the transient when compared to minimum operating bolt load after gasket relaxation effect has been accounted for, establishes that that the gasket will continue to seal during the 1st thermal cycle transient load has been applied.  The detailed FEA analysis simulated the loss of additional gasket seating stress due to the inherent design of ‘Eccentric steam-inlet’ line causing a non-uniform thermal gradient to be within acceptable range. However, upon completing a further thorough ASME PCC-1 analysis in accordance with the WRC-538, it established that the existing spiral wound gasket required a target assembly gasket seating stress of 17,824psi, consequentially requiring a bolt tensioning value of 61ksi to perform effectively. In general, during assembly, the bolt is pre-stress only upto to maximum of 45ksi. This has been attributed to the root cause of the chronic leak issue.Also it was established that the current flange design was limited to a bolt tensioning value of 52ksi, rendering the existing Flexitallic spiral-wound gasket unsuitable for the tubesheet flange joint design application. In conclusion, it has been established that the Flexitallic CHANGE gasket overcomes the limitation posed by the Spiral-wound gasket for application in the 10E-22 operating service.

|